Who we are?

Located in Development Zone-Changsha City, Suntek is one of the leading suppliers of EMS and has been providing support in PCB assembly and cable assembly field for more than 10 years. With ISO 9001:2015,ISO13485,IATF16949 and UL certified,we supply qualified products with competitive prices to clients all over the world.

What we do?

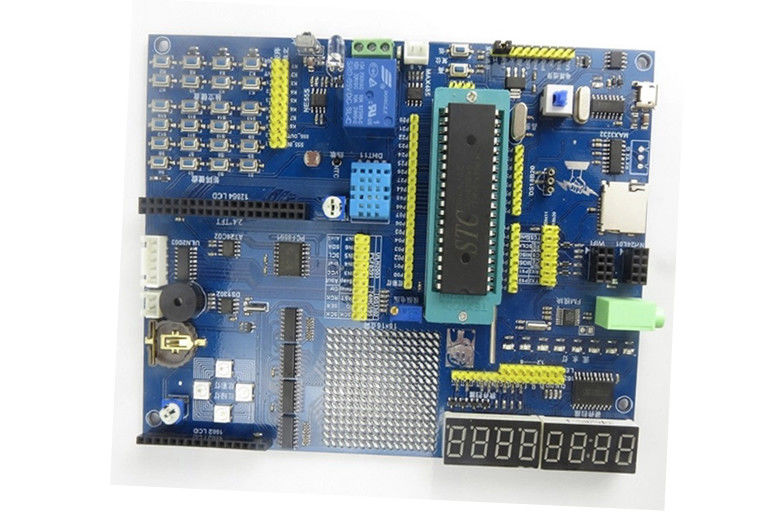

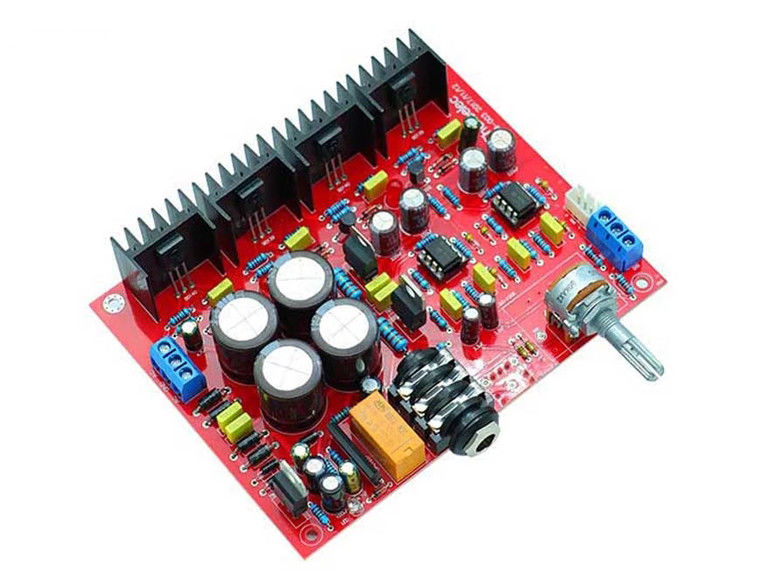

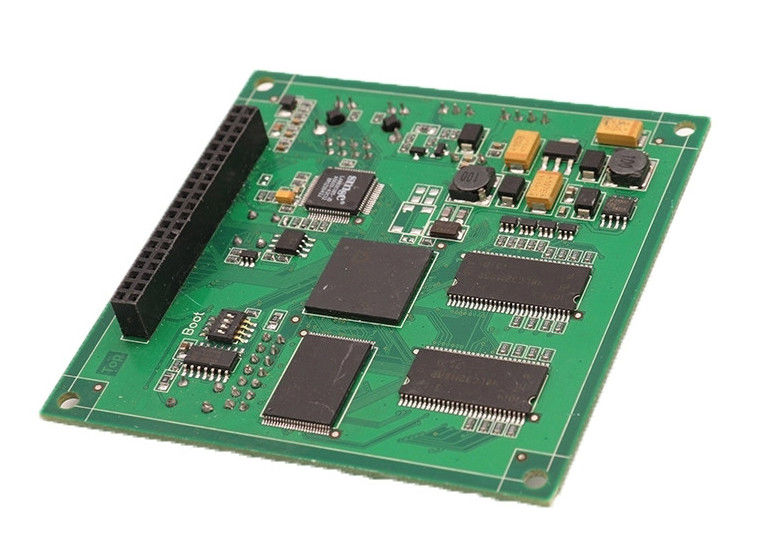

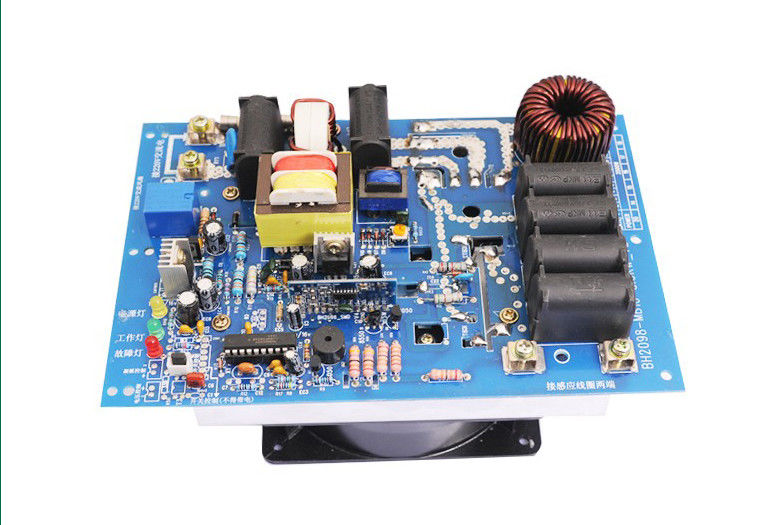

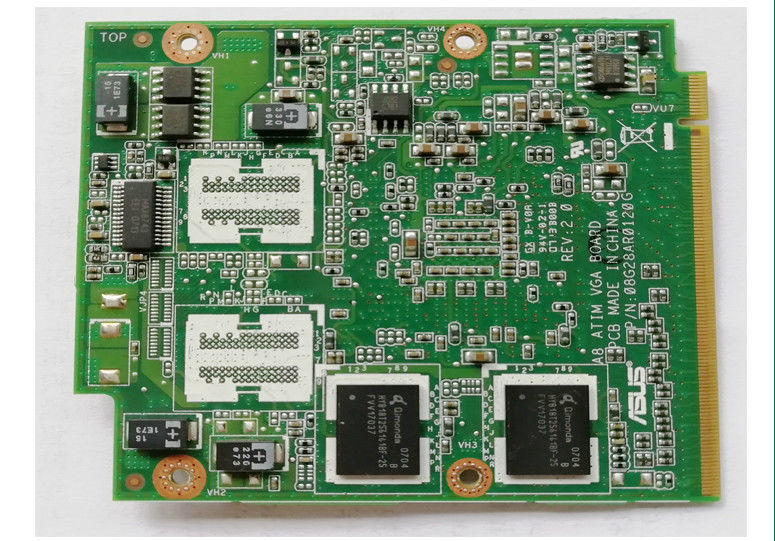

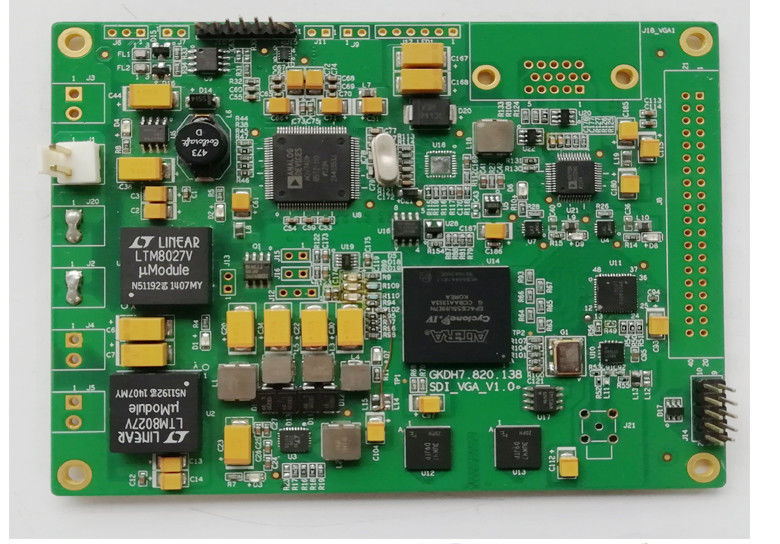

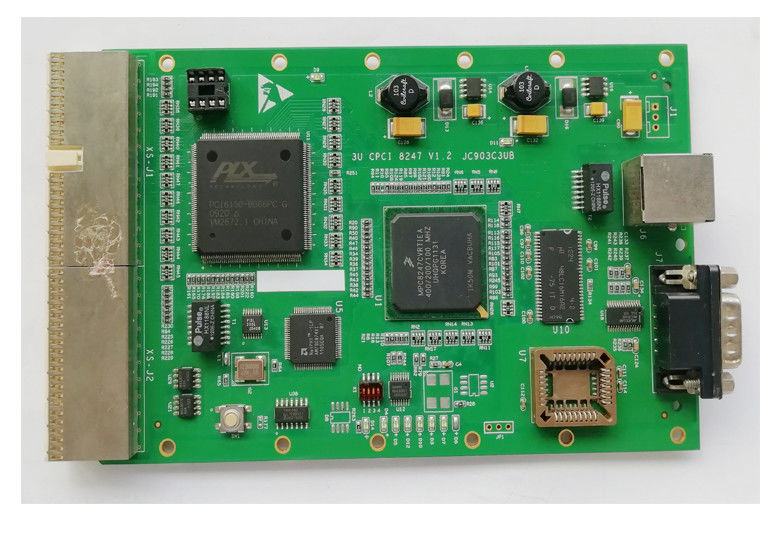

We provide one-stop solution for PCB assembly and cable assembly,both turnkey and consignee solutions,with strict adherence to RoHS regulations. Our products experience include consumer electronics,industrial products,telecommunications, medical equipment etc.No matter it is quick-turn prototype,short-run or high volume mass production.

Product Description:

| Project |

SMT processing capacity |

| SMT capacity |

10 million solder joints/day |

| Surplus |

Resistance and capacitance: 0.3% |

| IC: 0% |

| Board type |

POP/PCB/FPC/Rigid-flex board/HDI/High Frequency&Speed

PCB/Metal-PCB |

| Mounting component precision |

Minimum package: 03015CHIP/0.20PLT |

| Minimum Component Accuracy:±0.034MM |

| IC placement accuracy: ± 0.025MM |

| PCB SPEC |

PCB size: 50*50MM~774*710MM |

| PCB thickness: 0.3~6.5MM |

Certificates:

With ISO9001:2015,ISO13485:2016,IATF 16949:2016 and UL E476377 certified,

Equipment

We have advanced production equipments and Testing machines.

Applications:

We have advanced manufacturing equipments,professional technology,professional

engineer team,purchasing team,quality team and management team to guarantee

the high quality products and on time delivery.Our products are widely used in

industrial control,auto,telecommunications,medical equipment,consumer electronics and etc.

Assembly capabilities:

SMT Assembly, BGA Assembly, Through-Hole Assembly, Mixed Assembly, Rigid Flex PCB Assembly Services,

Electro Mechanical Assembly, Box Build Assembly, Product Assembly, Cable Assemblies.

Compliant with a wide range of standards including IPC 610 Class 2 and Class 3.

SMT PCB Assembly Process - Surface Mount Technology

In the fast-paced world of electronics manufacturing, surface mount technology (SMT) assembly is a pivotal innovation that has reshaped the way we produce printed circuit boards (PCBs). This article will take you on an in-depth look at the SMT assembly process as well as the pros and cons!

What is SMT assembly?

SMT, its full name is "surface-mount technology". SMT assembly is the method to place and solder the electronic components on the surface of PCB correctly by using automated machine. With the development of smart technology today, SMT assembly has replaced traditional through-holes technology construction method of fitting electronic components, SMT assembly allows to increase manufacturing automation so that it reduce the manufacturing cost of PCBs greatly and lead to smaller board.

Packaging and Shipping

Our Medical PCB Assembly products are carefully packaged and shipped to ensure their safe delivery to our customers. We understand the importance of maintaining the quality and integrity of our products, especially in the medical industry. That's why we follow strict packaging and shipping guidelines to ensure that our products arrive at their destination in perfect condition.

Our supports

We ensure cost transparency, BOM cost breakdown sharing

We have components suppliers from the Global.

We have a written process to advise customers of any schdule delays or product quality problems,by:

(1)Customer service procedure

(2)RMA procedure

(3)8D reports

(4)PDCA(Plan-Do-Check-Action) in customer service

We respond to the complaints,issues and queries in 24 hours, by:

(1) Weekly reports

(2) Customer supporting team to review communication times

(3) Customer satisfaction questionnaire

Aftersales services:

(1) 1-year guarantee period for all of products

(2) FOC repair

(3) Quick compensation parts to replace defectives.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!