Product Description:

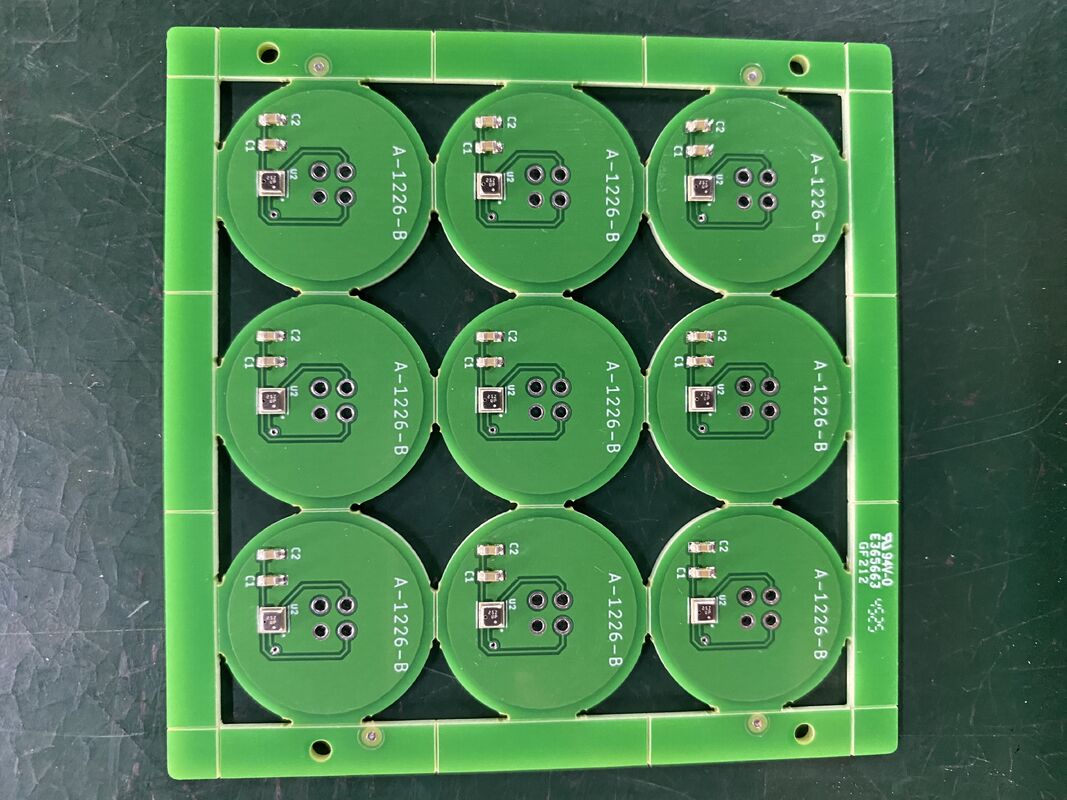

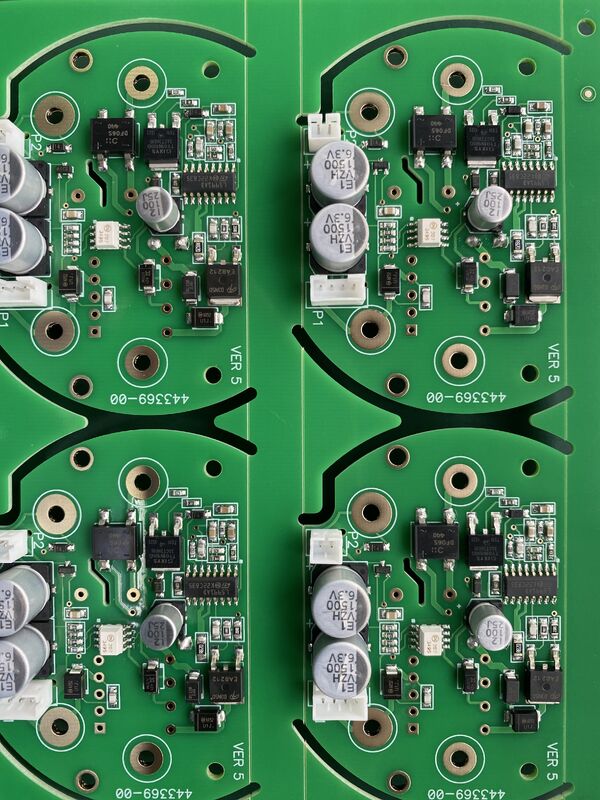

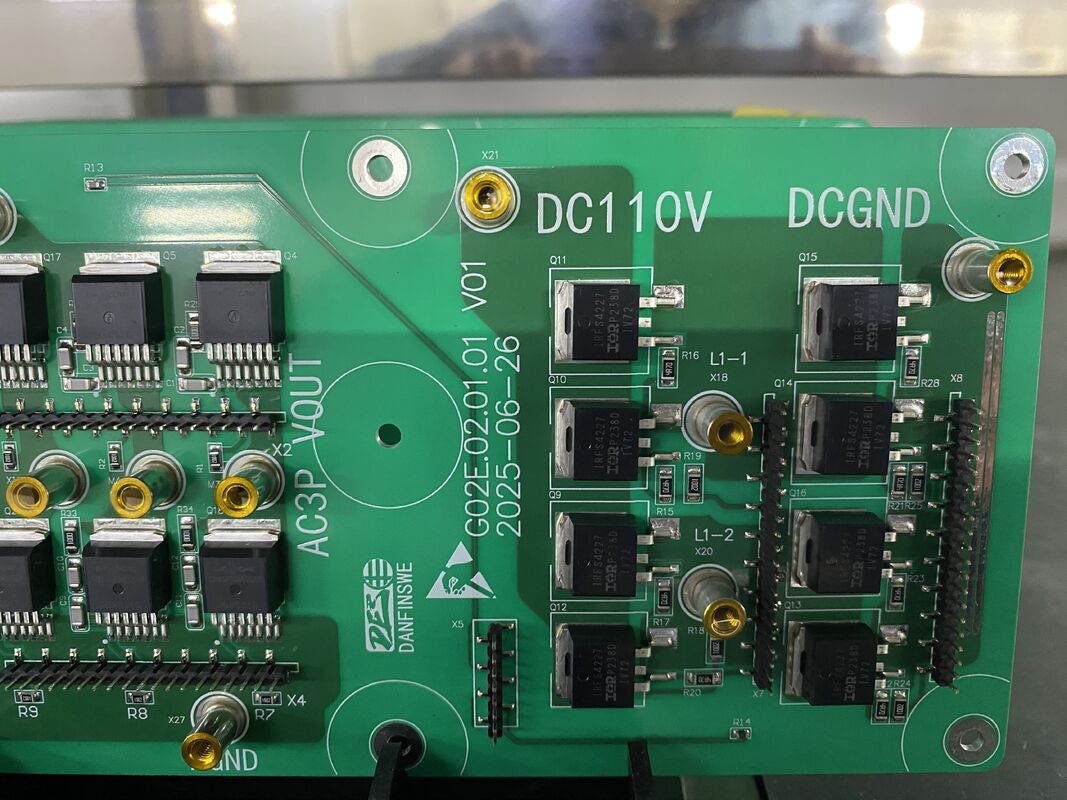

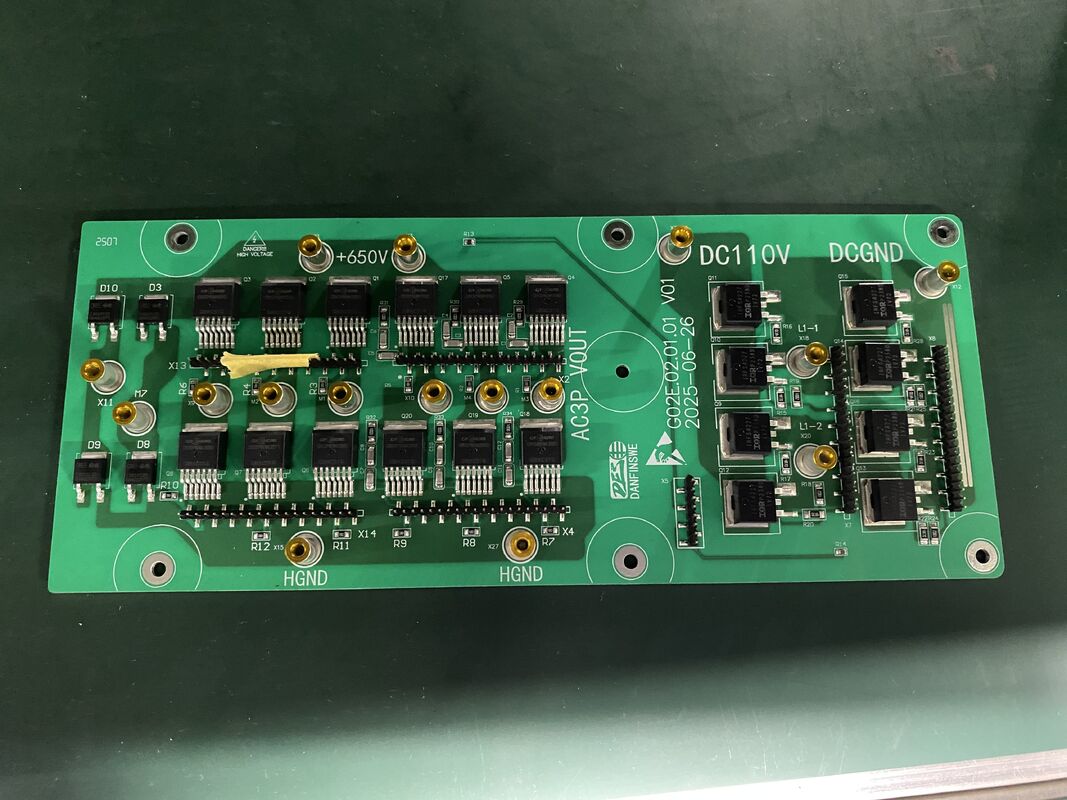

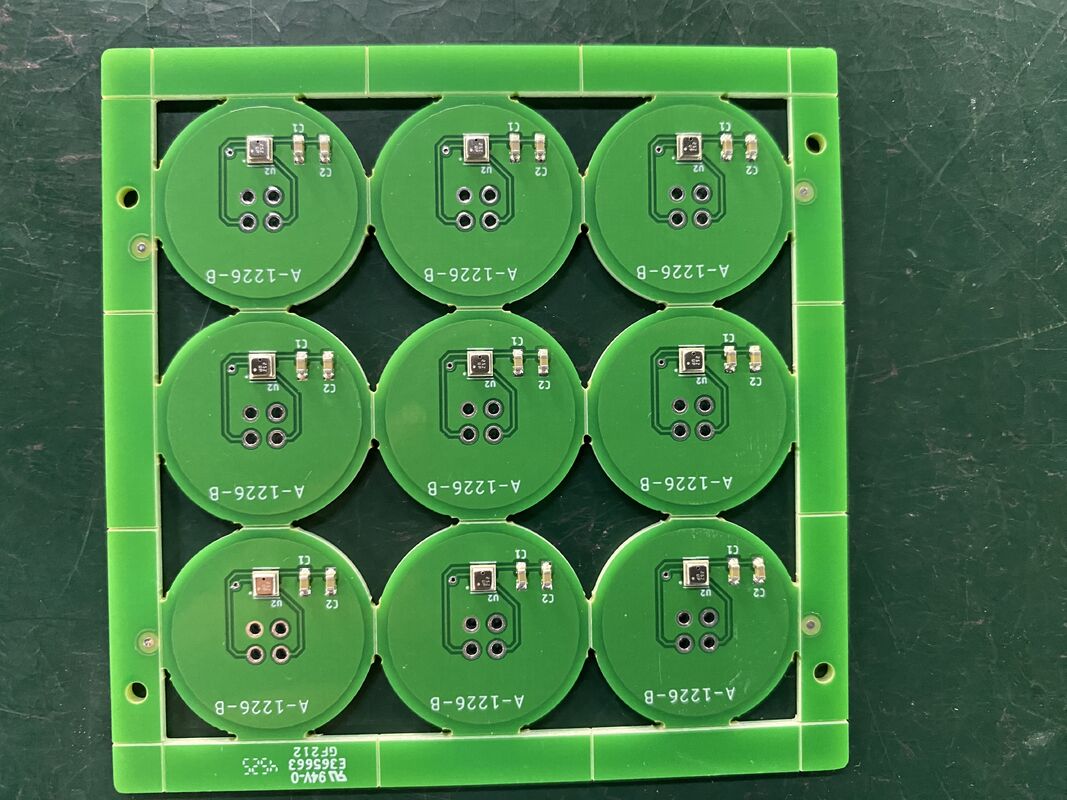

The Communication PCB Assembly is a highly advanced and reliable solution designed to meet the rigorous demands of modern communication infrastructure. This product stands out due to its exceptional build quality, incorporating cutting-edge materials and manufacturing techniques to ensure optimal performance in even the most challenging environments. Engineered with precision, this assembly is ideal for applications that require robust communication capabilities combined with the ability to handle heavy current loads efficiently.

One of the defining features of this Communication PCB Assembly is its surface finishing options. It is available with ENIG (Electroless Nickel Immersion Gold) and HASL (Hot Air Solder Leveling) lead-free finishes, which provide excellent solderability and superior protection against oxidation and corrosion. The ENIG finish, in particular, is well-regarded for its flat surface and reliable performance in high-frequency communication circuits, making it a perfect choice for advanced HDI PCB applications. The HASL lead-free finish ensures compliance with environmental standards while maintaining excellent mechanical and electrical properties.

The assembly supports a minimum hole diameter of 0.1mm, allowing for the creation of high-density interconnects that are essential in modern communication devices. This precision drilling capability enables the integration of intricate circuit designs and supports the miniaturization trend in communication infrastructure hardware. The small hole diameter, combined with advanced PCB manufacturing techniques, ensures that the assembly can accommodate complex routing and layering requirements without compromising signal integrity or mechanical strength.

Furthermore, this product features versatile via types, including through-hole, blind, and buried vias. These via types are critical in HDI PCB designs, as they facilitate multi-layer connections and enhance the overall electrical performance of the board. Through-hole vias provide robust mechanical connections and are ideal for components that require strong solder joints. Blind vias connect outer layers to inner layers without passing through the entire board, thereby saving space and reducing signal path lengths. Buried vias connect internal layers only, further optimizing the board layout and allowing for higher circuit density. This combination of via types enables the Communication PCB Assembly to deliver superior signal integrity and reliability, essential for heavy current applications within communication infrastructure systems.

The board thickness of this assembly ranges from 0.2mm to 6mm, offering flexibility to suit various application requirements. Thinner boards are ideal for compact, lightweight devices, while thicker boards provide enhanced durability and support for heavy current loads. This wide range in thickness selection ensures that the assembly can be tailored to meet specific mechanical and electrical demands, making it suitable for a broad spectrum of communication infrastructure projects.

At the core of this product is the HDI PCB technology, which stands for High-Density Interconnect Printed Circuit Board. HDI PCBs are known for their superior circuit density, enhanced electrical performance, and space-saving advantages. The use of HDI technology in this Communication PCB Assembly allows for the integration of complex circuitry in a compact form factor, enabling faster signal transmission and reduced power consumption. This is particularly important in communication infrastructure where efficient data transfer and reliable heavy current handling are paramount.

Designed to withstand the rigorous conditions of heavy current applications, this assembly ensures stable and uninterrupted operation in communication infrastructure systems. The ability to handle heavy current loads without degradation in performance or reliability makes it an indispensable component for power-intensive communication equipment. Whether it is used in base stations, network routers, or other critical infrastructure components, this Communication PCB Assembly provides the dependable performance required to maintain seamless connectivity.

In summary, the Communication PCB Assembly is a state-of-the-art solution that combines advanced surface finishing options such as ENIG and HASL lead-free, a minimum hole diameter of 0.1mm, versatile via types including through-hole, blind, and buried, and a wide board thickness range of 0.2mm to 6mm. Built on HDI PCB technology, it is specifically designed to support heavy current requirements within communication infrastructure, delivering exceptional reliability, durability, and electrical performance. This makes it an ideal choice for engineers and manufacturers seeking a high-quality PCB assembly capable of meeting the demanding challenges of modern communication systems.

Features:

- Product Name: Communication PCB Assembly

- Manufacturer: Reliable and experienced manufacturer ensuring high-quality standards

- Pcb Layers: 6 Layers for complex circuit designs

- Impedance Control: Yes, for optimal signal integrity

- Board Thickness: 0.2-6mm suitable for various application requirements

- Thick Copper: Supports heavy current capacity and enhanced durability

- Surge Protection: Integrated to safeguard sensitive communication components

- Outer Package: Carton packaging for secure and safe transportation

Technical Parameters:

| Product Name |

Communication PCB Assembly |

| Viatype |

Through Hole, Blind, Buried |

| Customized |

Yes |

| Surface Finishing |

ENIG, HASL Lead Free |

| Application Field |

5G Communication |

| Board Thickness |

0.2-6mm |

| Impedance Control |

Yes |

| Min Hole Diameter |

0.1mm |

| Communication PCB |

High Tg170 and High Tg180 |

| Outer Package |

Carton |

Applications:

The Communication PCB Assembly is an essential component designed specifically for robust communication infrastructure applications. Its customized PCB size allows for flexibility in design, ensuring it meets the unique requirements of various communication devices and systems. This product is ideal for use in environments where reliable and high-performance communication is critical, such as data centers, telecommunication hubs, and network equipment installations.

One of the key application occasions for this Communication PCB Assembly is in the development and maintenance of advanced communication infrastructure. The assembly supports through hole, blind, and buried vias, enabling complex multilayer designs that enhance signal integrity and reliability. This versatility makes it suitable for use in routers, switches, and other networking hardware that demand precise electrical performance and durability.

The product’s surface finishing options, including ENIG and HASL Lead Free, ensure excellent solderability and corrosion resistance, which are vital for long-term operation in harsh or variable environmental conditions. Additionally, the PCB assembly complies with ROHS quality standards, guaranteeing an environmentally friendly product that meets international safety and health regulations.

Thick copper layers are a prominent feature in this PCB assembly, providing superior current-carrying capacity and enhanced thermal management. This makes it perfect for power-intensive communication devices that require efficient heat dissipation and stable electrical performance. The thick copper also contributes to the mechanical strength of the PCB, ensuring durability in demanding application scenarios.

The outer packaging is made from sturdy carton material, offering reliable protection during shipping and handling. This ensures that the PCB assemblies arrive in excellent condition, ready for immediate integration into communication systems.

In summary, the Communication PCB Assembly is well-suited for a wide range of application scenarios within the communication infrastructure sector. Its customizable PCB size, multiple viatype capabilities including through hole, blind, and buried vias, ROHS compliance, and superior surface finishing options make it a dependable choice. The inclusion of thick copper layers further enhances its suitability for high-performance, durable communication equipment used in critical network environments.

Customization:

Our Communication PCB Assembly product offers comprehensive customization services to meet your specific needs. With precise impedance control, we ensure optimal signal integrity crucial for high-frequency 5G communication applications. Customers can choose from a variety of solder mask colors, including blue, green, and others, to suit their design preferences.

As a reliable Manufacturer, we adhere strictly to the ROHS quality system, guaranteeing environmentally friendly and high-quality PCB assemblies. Our Communication PCBs are built with High Tg170 and High Tg180 materials, providing excellent thermal stability and durability for demanding environments.

Designed to support heavy current loads and incorporate advanced surge protection features, our PCBs are ideal for robust communication systems. Trust our tailored solutions to enhance the performance and reliability of your 5G communication devices.

Support and Services:

Our Communication PCB Assembly product is backed by comprehensive technical support and services to ensure optimal performance and reliability. We provide detailed documentation, including assembly instructions, testing procedures, and troubleshooting guides to facilitate smooth integration and maintenance.

Our experienced technical support team is available to assist with design inquiries, component selection, and process optimization to meet your specific communication application requirements. We offer customized testing services to verify signal integrity, impedance matching, and overall functionality of the PCB assemblies.

Additionally, we provide repair and rework services to address any issues that may arise during the product lifecycle, ensuring minimal downtime and sustained operational efficiency. Our commitment to quality and customer satisfaction extends through every stage of the product’s use.

For ongoing support, we offer software updates and firmware upgrades where applicable, as well as training sessions to help your team maximize the benefits of our Communication PCB Assembly solutions.

Packing and Shipping:

Our Communication PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each assembly is securely placed in anti-static bags to prevent electrostatic discharge, then cushioned with foam inserts or bubble wrap to avoid physical damage. The packaged units are finally placed in sturdy, appropriately sized boxes to minimize movement and impact.

For shipping, we partner with reliable carriers to provide timely and safe delivery worldwide. All shipments include tracking information and are insured to safeguard against loss or damage. We also offer customized packaging solutions upon request to meet specific client requirements.

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!