Product Description:

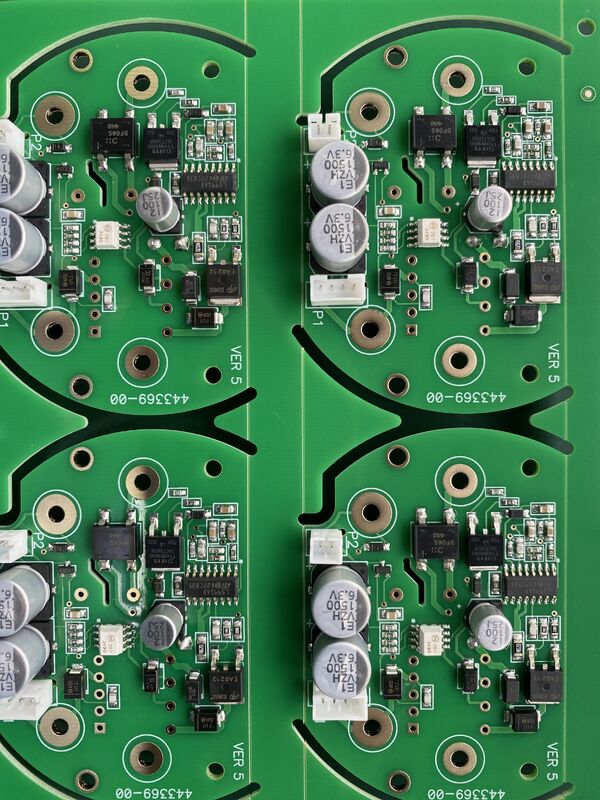

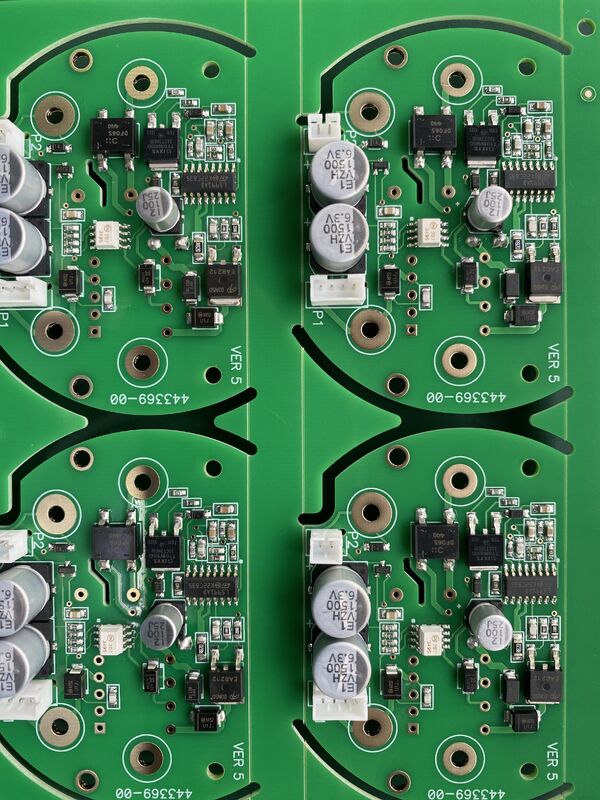

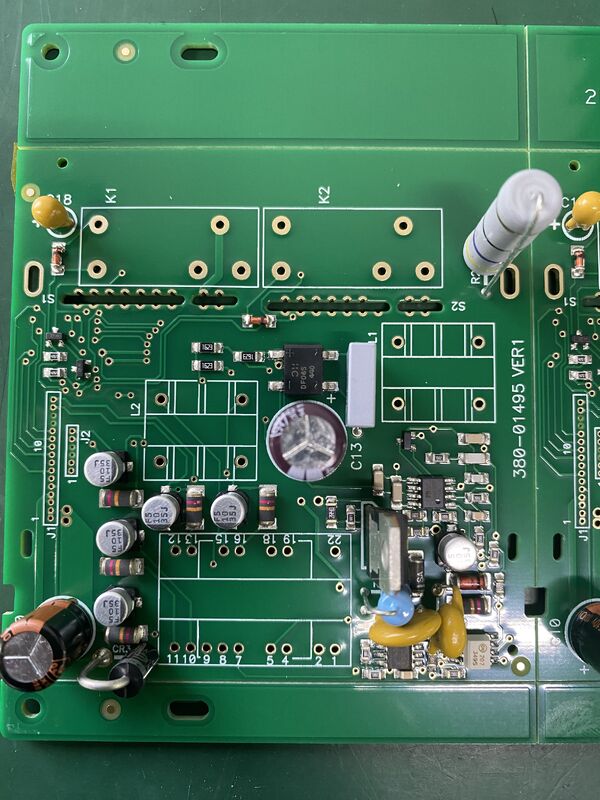

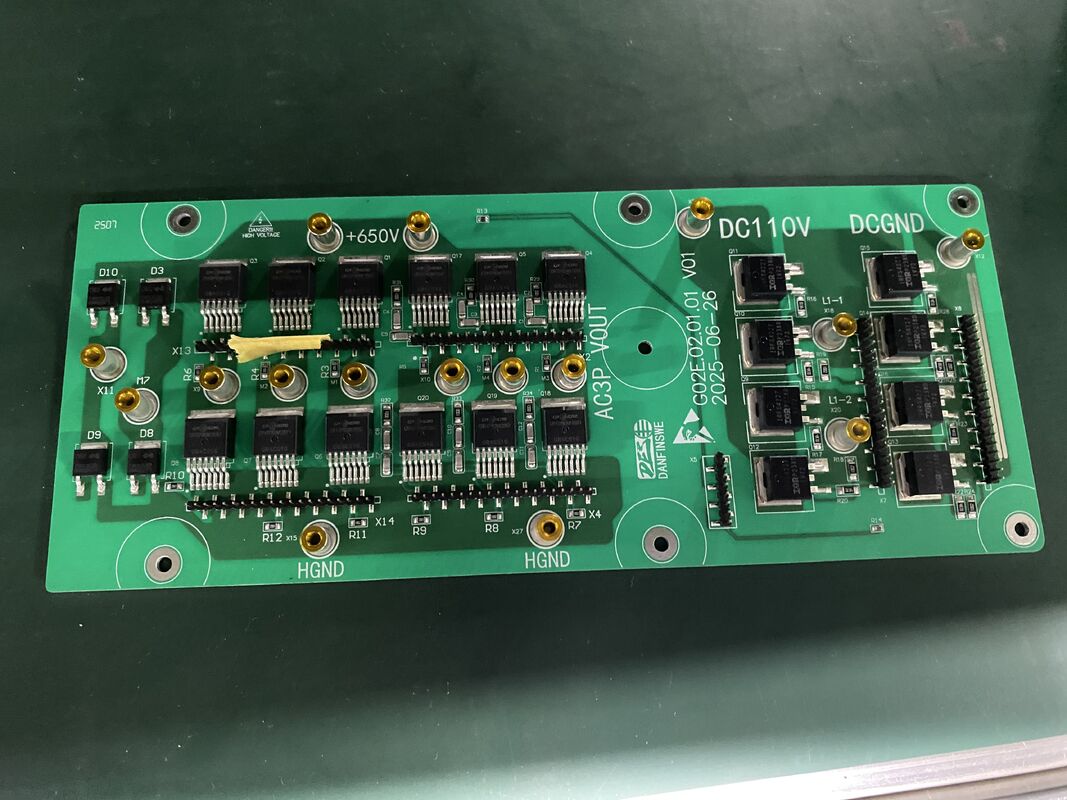

Our Industrial PCB Assembly product offers a comprehensive solution for businesses requiring high-quality, reliable, and durable printed circuit boards tailored specifically for industrial applications. Designed to meet the stringent demands of industrial environments, this product combines advanced materials, precise manufacturing processes, and robust specifications to ensure optimal performance and longevity in a variety of industrial electronic systems.

One of the standout features of our Industrial PCB Assembly is its versatile thickness range, spanning from 0.3mm to 6mm. This flexibility allows for customized board designs that can cater to different industrial electronic requirements, whether it involves compact, lightweight assemblies or more rugged, heavy-duty boards. For applications requiring extra durability and strength, our product supports a maximum thickness of over 4.5mm (T>4.5mm), making it ideal for high-stress environments where mechanical stability is essential.

The copper weight used in our Industrial PCB Assembly is 4OZ, ensuring excellent electrical conductivity and efficient heat dissipation. This thicker copper layer is particularly advantageous in industrial electronic circuit assembly, where reliable current carrying capacity and thermal management are critical for the performance and safety of the final product. The enhanced copper thickness contributes to the robustness and longevity of the PCB, making it suitable for use in power electronics, motor controllers, and other demanding industrial applications.

Our Industrial PCB Assembly solutions also accommodate large-sized boards, with a maximum PCB size of 600*1200mm. This capability supports the production of complex assemblies and large-scale industrial electronic circuits, enabling manufacturers to integrate multiple functionalities on a single board while maintaining high assembly precision and quality. The ability to handle large PCBs ensures that our clients can develop scalable industrial electronics solutions without compromising on performance or reliability.

The base material used for our Industrial PCB Assembly is FR4, a widely recognized and trusted substrate in the electronics industry. FR4 provides excellent mechanical strength, moisture resistance, and electrical insulation properties, making it an ideal choice for industrial electronics assembly service providers. The high-quality FR4 base material ensures that the PCB can withstand harsh industrial conditions such as temperature fluctuations, humidity, and mechanical stress, thereby enhancing the overall durability and reliability of the assembled electronic circuits.

With our Industrial PCB Assembly solutions, customers benefit from a seamless integration of design, fabrication, and assembly processes tailored to industrial needs. Our Industrial Electronics Assembly Service is committed to delivering precision-engineered circuit boards that meet rigorous industry standards and certifications. Whether you require prototyping or mass production, our service ensures consistent quality, timely delivery, and technical support throughout the entire product lifecycle.

In summary, our Industrial PCB Assembly product is a robust, flexible, and high-performance solution for industrial electronic circuit assembly needs. Featuring a thickness range from 0.3mm to 6mm, a copper weight of 4OZ, a maximum thickness capability beyond 4.5mm, and support for large PCB sizes up to 600*1200mm, all built upon a reliable FR4 base material, this product is engineered to excel in industrial environments. Coupled with our expert Industrial Electronics Assembly Service, it represents a comprehensive offering for businesses seeking dependable and scalable industrial PCB assembly solutions.

Features:

- Product Name: Industrial PCB Assembly

- Thickness Range: 0.3mm - 6mm

- Material Options: FR4, CEM-1, CEM-3

- PCB Thickness: 0.2mm - 3.2mm

- Warranty Period: 1 Year

- Impedance Control: Yes

- Suitable for Industrial Printed Circuit Assembly applications

- Ideal for Industrial Circuit Board Assembly requirements

- Supports Industrial PCB Fabrication Assembly processes

Technical Parameters:

| Max PCB Size |

600*1200mm |

| Silkscreen Color |

White, Black, Yellow, Etc. |

| Max Thickness |

T > 4.5mm |

| Impedance Control |

Yes |

| Copper |

4OZ |

| Customized |

Yes |

| Material |

FR4, CEM-1, CEM-3 |

| Min Ball Space |

0.3mm ≤ Pitch < 0.5mm |

| Thickness |

0.3mm - 6mm |

| PCB Thickness |

0.2 - 3.2mm |

Applications:

Industrial Printed Circuit Board Assembly plays a critical role in various industrial applications where precision, durability, and reliability are paramount. Utilizing high-quality FR4 as the base material, these PCBs offer exceptional mechanical strength and excellent electrical insulation, making them ideal for demanding industrial environments. With PCB thickness ranging from 0.2mm to 3.2mm, manufacturers can customize the boards to meet specific mechanical and electrical requirements, ensuring optimal performance across diverse applications.

One of the primary application occasions for Industrial Printed Circuit Board Assembly is in OEM electronics production. Many industries rely on customized Industrial PCB Fabrication Assembly to develop tailor-made solutions that perfectly fit their unique product designs. Whether it’s automation equipment, control systems, or instrumentation devices, customized PCBs ensure seamless integration and enhanced functionality.

The versatility in PCB size, with a maximum dimension of 600*1200mm, allows for large-scale industrial projects that demand extensive circuitry on a single board. This is particularly beneficial in heavy machinery, power distribution units, and complex control panels, where space optimization and efficient circuit layout are critical. Industrial PCB Manufacturing Assembly with such size capabilities supports innovation and complexity in industrial electronics design.

Industrial PCB Fabrication Assembly is also essential in scenarios such as robotics, aerospace electronics, and automotive manufacturing. These industries require PCBs that can withstand harsh conditions, including high temperatures, mechanical stress, and exposure to chemicals. The use of FR4 base material ensures durability and long-term reliability, which are indispensable for safety-critical applications.

Moreover, Industrial Printed Circuit Board Assembly is frequently employed in renewable energy systems, medical equipment, and telecommunications infrastructure. Each of these sectors demands high-quality, customized PCB assemblies that align with strict industry standards and specific operational needs. The capability to customize thickness and size further enhances the adaptability of these PCBs to various scenario requirements.

In summary, Industrial PCB Manufacturing Assembly is integral to modern industrial electronics, providing robust, customizable, and reliable circuit board solutions. Whether for OEM electronics or specialized industrial applications, these assemblies ensure superior performance and longevity, fulfilling the rigorous demands of today’s fast-evolving industrial landscape.

Customization:

Our Industrial PCB Assembly services offer fully customized solutions to meet the specific needs of your projects. We specialize in Industrial Electronic Circuit Assembly, providing high-quality boards with 4OZ copper thickness to ensure superior conductivity and durability. Using premium materials such as FR4, CEM-1, and CEM-3, we guarantee robust performance and reliability in various industrial applications.

With precise impedance control, our Industrial PCB Assembly Solutions ensure optimal signal integrity and performance for complex electronic designs. We accommodate board thicknesses ranging from 0.3mm to 6mm, allowing flexibility to suit diverse industrial requirements.

Our commitment to quality is backed by a 1-year warranty, giving you confidence in the longevity and functionality of your Industrial Electronic Board Assembly. Trust us to deliver tailored Industrial PCB Assembly services that meet your exact specifications and enhance your electronic manufacturing process.

Support and Services:

Our Industrial PCB Assembly product is backed by comprehensive technical support and service to ensure optimal performance and reliability. Our team of experts is dedicated to assisting you with installation, troubleshooting, and maintenance to maximize your production efficiency.

We provide detailed documentation, including user manuals, assembly guidelines, and testing procedures to facilitate seamless integration into your manufacturing process. Should you encounter any issues, our technical support specialists are available to guide you through problem resolution and provide timely solutions.

Additionally, we offer customized training sessions tailored to your team’s specific needs, helping them gain the necessary skills to handle the assembly equipment effectively. Our commitment to quality extends to continuous product updates and enhancements based on customer feedback and technological advancements.

For any service inquiries, maintenance requests, or further assistance, our support team is ready to ensure your Industrial PCB Assembly operations run smoothly and efficiently.

Packing and Shipping:

Our Industrial PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each PCB is placed in anti-static bags and cushioned with foam inserts to prevent any damage from shocks or vibrations. The assemblies are then secured within sturdy, double-walled cardboard boxes designed to withstand handling and environmental factors.

For shipping, we utilize reliable carriers that offer tracking and insurance options to guarantee safe and timely delivery. All packages are clearly labeled with handling instructions and product details to facilitate smooth customs clearance and minimize delays. We also offer expedited shipping options for urgent orders to meet your project deadlines efficiently.

FAQ:

Q1: What types of components can be assembled on the Industrial PCB Assembly?

A1: Our Industrial PCB Assembly supports a wide range of components including surface-mount devices (SMD), through-hole components, and mixed technology parts, ensuring versatility for various industrial applications.

Q2: What is the typical turnaround time for an Industrial PCB Assembly order?

A2: The standard turnaround time is between 5 to 15 business days, depending on the complexity and quantity of the assembly. Expedited services are available upon request.

Q3: What quality standards does the Industrial PCB Assembly comply with?

A3: Our PCB assemblies adhere to rigorous quality standards such as IPC-A-610 Class 2 and Class 3, ensuring reliable performance in industrial environments.

Q4: Can you handle high-volume production runs for Industrial PCB Assembly?

A4: Yes, we are equipped to manage both small prototype orders and large-scale industrial production runs with consistent quality and efficiency.

Q5: What design file formats are accepted for the Industrial PCB Assembly process?

A5: We accept common PCB design file formats including Gerber (RS-274X), ODB++, and IPC-2581 to facilitate accurate and efficient assembly.

PCBA Equipment

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!