Product Description:

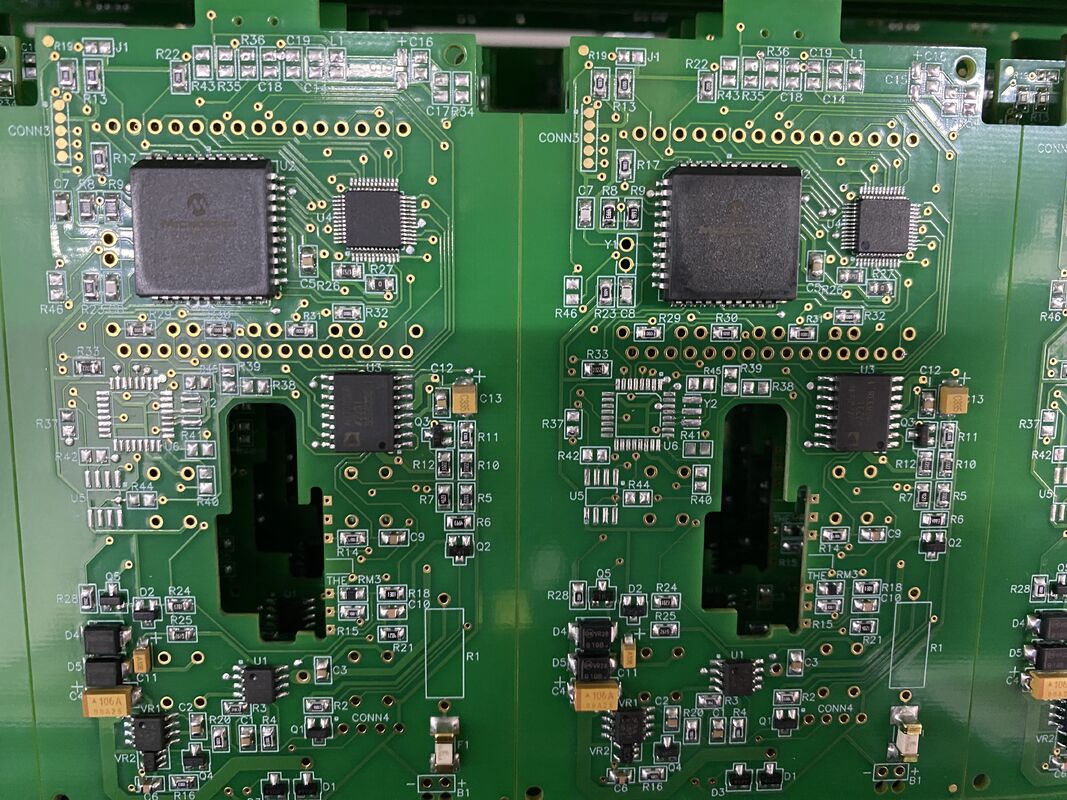

Our Industrial PCB Assembly service is designed to meet the rigorous demands of modern manufacturing and industrial applications. With a focus on precision, reliability, and durability, this service ensures that your industrial electronic boards are assembled to the highest standards, supporting a wide range of industrial electronic circuit assembly needs. Whether you require prototypes or high-volume production, our Industrial Electronics Assembly Service delivers exceptional quality and performance.

One of the key features of our Industrial PCB Assembly is the versatility in board thickness, ranging from 0.3mm to 6mm. This wide thickness range allows us to cater to various industrial applications that demand different mechanical strengths, thermal properties, and electrical characteristics. Thicker boards are ideal for heavy-duty industrial environments, while thinner boards suit compact and lightweight designs, ensuring flexibility to match your specific project requirements.

We provide multiple soldermask color options including green, red, blue, black, white, and yellow. This variety not only enhances the aesthetic appeal of the industrial electronic boards but also helps in identifying different boards or layers quickly during assembly and maintenance processes. The choice of soldermask color can be customized according to your branding or functional preferences, contributing to a professional and organized manufacturing workflow.

Our PCB assembly service supports a maximum PCB size of up to 600mm by 1200mm, accommodating large industrial electronic circuit assemblies that require expansive board real estate. This capability is crucial for industrial sectors where complex circuitry and multiple components must be integrated on a single board to optimize performance and reduce space.

To guarantee the highest quality and reliability, we implement comprehensive testing services including 100% Automated Optical Inspection (AOI), Functional Circuit Testing (FCT), and In-Circuit Testing (ICT). These rigorous testing procedures ensure that each industrial electronic board assembly is free from defects, meets all electrical specifications, and functions flawlessly in its intended industrial application. Our commitment to quality testing reduces downtime and increases the overall reliability of your industrial electronics assembly service.

The copper thickness used in our PCB assemblies is 4OZ, providing excellent conductivity and durability. This heavier copper weight is particularly beneficial for industrial electronic boards that carry higher current loads or require enhanced thermal management. The robust copper layer ensures stable electrical performance and longevity even under harsh industrial conditions.

Our Industrial Electronics Assembly Service is tailored to support a broad spectrum of industries including automotive, aerospace, manufacturing automation, energy, and telecommunications. We understand the critical nature of industrial electronic circuit assemblies and strive to deliver products that meet stringent industry standards and certifications.

In summary, our Industrial PCB Assembly combines advanced manufacturing techniques with customizable options such as thickness ranging from 0.3mm to 6mm, multiple soldermask colors, large PCB size capacity up to 600*1200mm, and robust 4OZ copper layers. Coupled with 100% AOI, FCT, and ICT testing services, we ensure that every industrial electronic board assembly we produce meets the highest levels of quality, reliability, and performance. Trust our Industrial Electronics Assembly Service to bring your complex industrial electronic circuit assembly projects to life with precision and efficiency.

Features:

- Product Name: Industrial PCB Assembly

- Material Options: FR4, CEM-1, CEM-3

- Maximum PCB Size: 600*1200mm

- Thickness Range: 0.3mm - 6mm

- Silkscreen Colors Available: White, Black, Yellow, and more

- Warranty: 1 Year

- Specialized in Industrial Electronic Circuit Assembly

- Comprehensive Industrial Electronics Assembly Service

- Reliable Industrial Electronics Assembly Service for various applications

Technical Parameters:

| Customized |

Yes |

| Soldermask Color |

Green, Red, Blue, Black, White, Yellow |

| Usage |

OEM Electronics |

| Min Ball Space |

0.3mm ≤ Pitch < 0.5mm |

| PCB Thickness |

0.2 - 3.2mm |

| Warranty |

1 Year |

| Max Thickness |

T > 4.5mm |

| Testing Service |

100% AOI, FCT, ICT Testing |

| Copper |

4OZ |

| Silkscreen Color |

White, Black, Yellow, Etc. |

Applications:

Industrial PCB Assembly Solutions are essential in a wide range of application occasions and scenarios where reliability, precision, and durability are paramount. These solutions are designed to meet the stringent demands of modern industrial environments, ensuring that electronic components function flawlessly under various conditions. Utilizing high-quality materials such as FR4, CEM-1, and CEM-3, with a base material predominantly FR4, these assemblies provide exceptional mechanical strength and thermal stability, making them ideal for industrial applications.

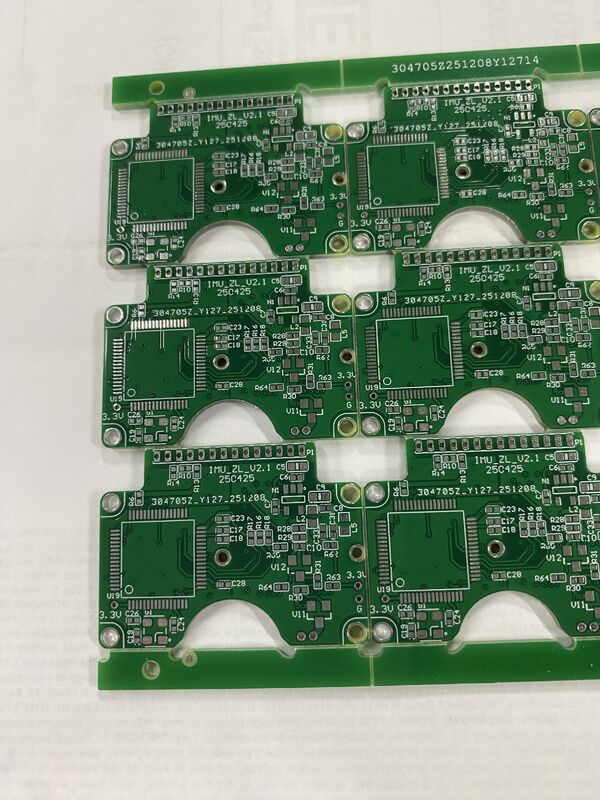

The Industrial Printed Circuit Board Assembly is commonly employed in manufacturing automation systems, where complex control circuits require robust and reliable PCBs to maintain continuous operation. In factory automation, robotics, and CNC machinery, the precision of the PCB assembly is critical. The min ball space of 0.3mm to less than 0.5mm pitch enables the accommodation of fine-pitch components, which is vital for compact and high-density designs frequently used in industrial electronics.

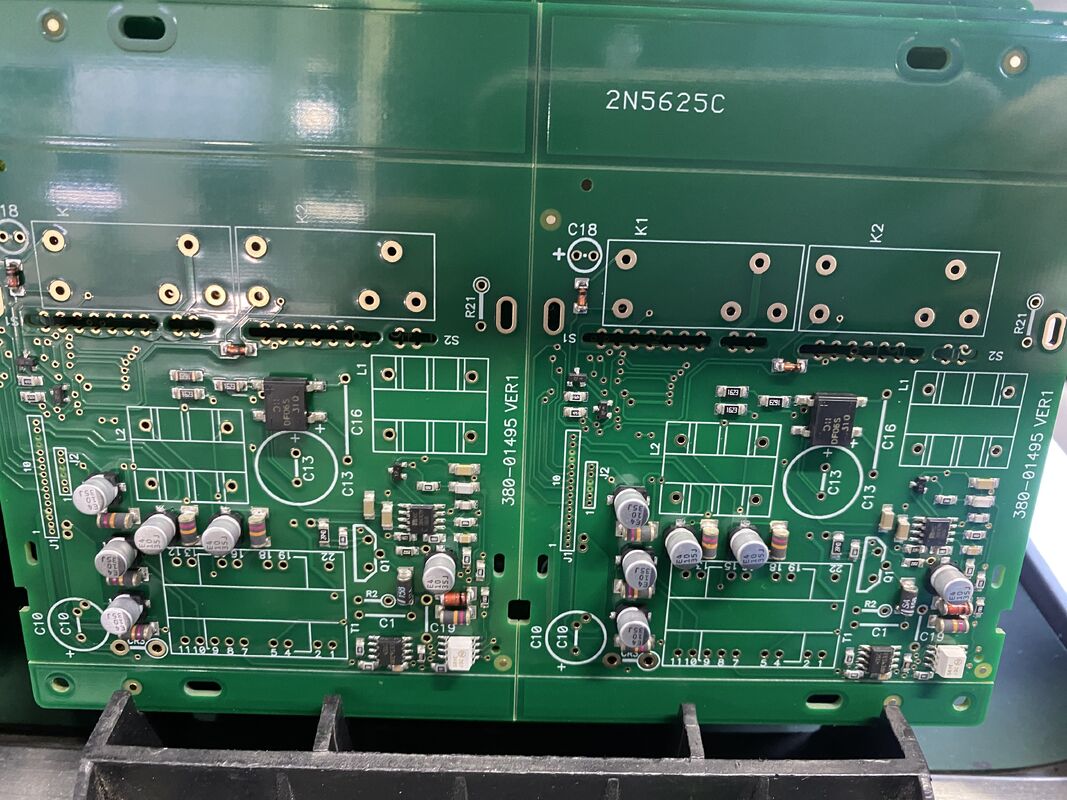

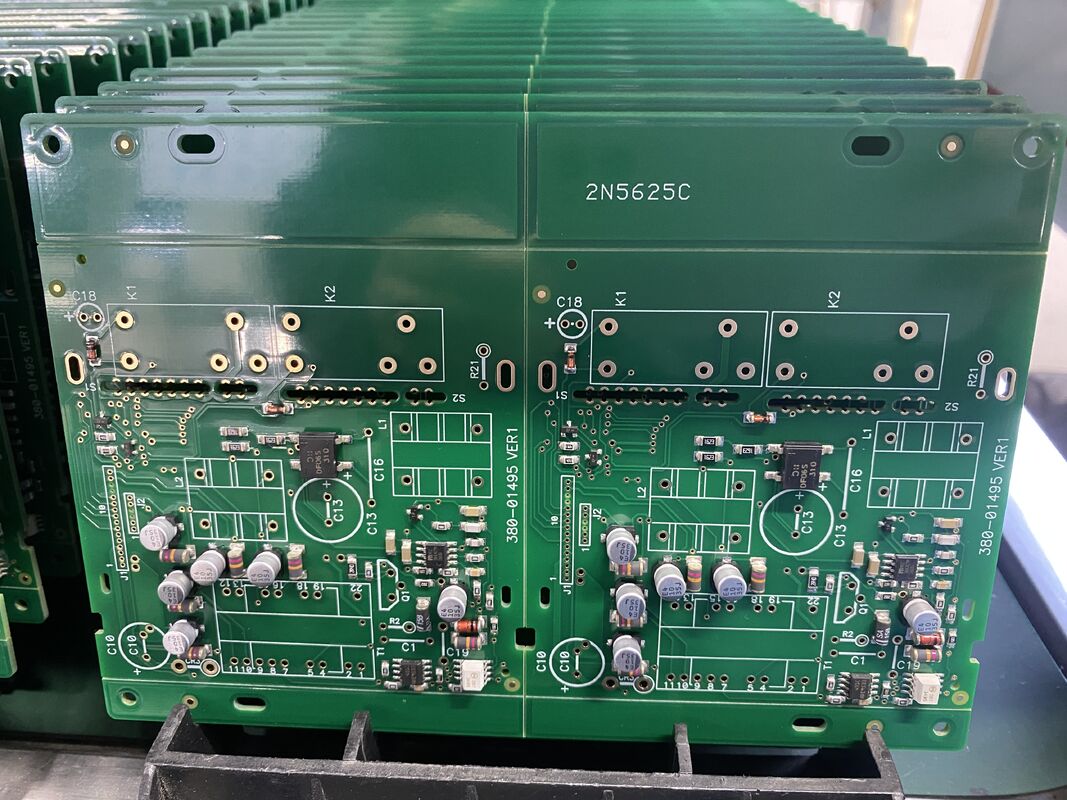

Another significant scenario for Industrial Electronics Assembly Service is in the development and maintenance of power management systems, including inverters, converters, and motor controllers. These systems demand PCBs that can endure harsh environments, including exposure to heat, vibration, and electrical noise. The use of materials like FR4 and CEM-3 ensures the assemblies possess excellent insulation properties and durability.

Moreover, Industrial PCB Assembly Solutions are indispensable in sectors such as transportation, energy, and telecommunications. For instance, control units in electric vehicles or renewable energy installations require reliable PCB assemblies that can handle high currents and voltage variations. The comprehensive 100% AOI (Automated Optical Inspection), FCT (Functional Circuit Testing), and ICT (In-Circuit Testing) services guarantee that every PCB assembly meets rigorous quality standards, minimizing the risk of failure in critical applications.

With a warranty of one year, these Industrial Printed Circuit Board Assemblies provide customers with confidence in product longevity and performance. The combination of advanced materials, precise assembly techniques, and thorough testing services makes these industrial electronics assembly services highly suitable for applications where failure is not an option. Whether used in new product development or repair and maintenance, these Industrial PCB Assembly Solutions deliver dependable performance across diverse industrial scenarios.

Customization:

Our Industrial PCB Assembly services offer comprehensive customization to meet the specific needs of your projects. We specialize in Industrial Circuit Board Assembly with a focus on high-quality copper layers, providing a robust 4OZ copper thickness to ensure excellent conductivity and durability.

With a maximum PCB size of 600*1200mm, we can accommodate large-scale Industrial Electronic Circuit Assembly requirements, delivering precise and reliable assemblies for complex applications. Our manufacturing process supports impedance control, guaranteeing signal integrity and optimal performance for sensitive electronic components.

We utilize premium FR4 as the base material, ensuring stability and excellent electrical insulation in every Industrial PCB Manufacturing Assembly. The PCB thickness can be customized within the range of 0.2-3.2mm, allowing flexibility to suit various design specifications and mechanical requirements.

Choose our Industrial PCB Assembly service for tailored solutions that combine advanced technology and meticulous craftsmanship to bring your electronic circuit designs to life with superior quality and reliability.

Support and Services:

Our Industrial PCB Assembly product comes with comprehensive technical support and services to ensure optimal performance and reliability. We offer expert consultation to assist with design optimization, material selection, and process planning tailored to your specific industrial applications.

Our technical support team is available to provide troubleshooting assistance, firmware updates, and maintenance guidelines to help you maximize the lifespan and efficiency of your PCB assemblies. We also provide detailed documentation, including assembly instructions, testing procedures, and quality assurance protocols.

In addition, we offer custom testing services such as in-circuit testing, functional testing, and environmental stress screening to guarantee that each PCB assembly meets stringent industrial standards. Our repair and rework services are designed to minimize downtime and maintain production continuity.

To support your operational needs, we provide training sessions and workshops for your engineering and maintenance teams, ensuring they are well-versed in the best practices for handling and maintaining the PCB assemblies. Our commitment is to deliver not only high-quality products but also exceptional support and service throughout the product lifecycle.

Packing and Shipping:

Our Industrial PCB Assembly products are carefully packaged to ensure maximum protection during transit. Each PCB assembly is placed in anti-static bags to prevent electrostatic discharge, then securely cushioned with foam inserts inside sturdy, corrugated cardboard boxes.

For added safety, we use moisture barrier bags and desiccants when required to protect against humidity and environmental factors. All packages are clearly labeled with handling instructions and product details to facilitate smooth shipping and receiving processes.

We partner with reliable carriers to provide timely and secure delivery services worldwide. Tracking information is provided for every shipment, ensuring transparency and allowing customers to monitor their orders until they arrive safely at their destination.

Our packaging and shipping protocols are designed to maintain the integrity and quality of Industrial PCB Assemblies, minimizing the risk of damage and ensuring customer satisfaction.

FAQ:

Q1: What types of components can be assembled on the Industrial PCB Assembly?

A1: Our Industrial PCB Assembly supports a wide range of components including through-hole, surface mount devices (SMD), BGAs, and fine-pitch components, ensuring compatibility with diverse industrial applications.

Q2: What is the typical turnaround time for Industrial PCB Assembly orders?

A2: The standard turnaround time ranges from 7 to 15 business days depending on the complexity and quantity of the order. Expedited services are also available upon request.

Q3: Can you handle both prototype and mass production runs for PCB assembly?

A3: Yes, we accommodate both small prototype batches and large-scale mass production runs, offering flexible solutions tailored to your project needs.

Q4: What quality standards do you follow for Industrial PCB Assembly?

A4: Our assembly process adheres to industry standards such as IPC-A-610 and ISO 9001, ensuring high reliability and quality control throughout production.

Q5: Do you provide testing and inspection services for assembled PCBs?

A5: Yes, we offer comprehensive testing options including Automated Optical Inspection (AOI), X-ray inspection, and functional testing to verify assembly accuracy and performance.

PCBA Equipment

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!  귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다! 이메일을 확인하십시오!

이메일을 확인하십시오!